Kingsley Engineering Service Corporation is proud to be a key partner in a groundbreaking initiative to implement Zero Liquid Discharge (ZLD) technology in Bangladesh's textile sector. Funded by the FCDO (Foreign, Commonwealth, and Development Office) and implemented by UNCTAD (United Nations Conference on Trade and Development), this project aims to revolutionize our water management practices.

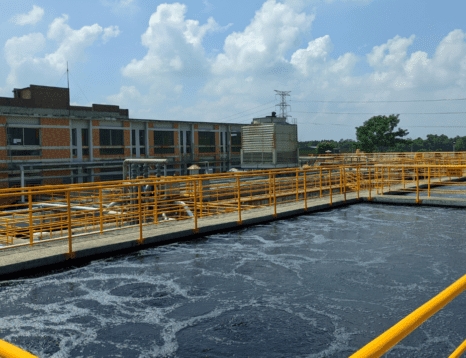

ZLD technology eliminates liquid waste from textile production. By treating, recovering, and reusing wastewater within a closed-loop system, ZLD drastically reduces reliance on freshwater and eliminates harmful wastewater discharge. This pilot project, running until September 2025, has the potential to achieve a remarkable 95% water savings and reuse rate.

Kingsley Engineering Service Corporation, alongside QStone Capital and LennTech, is developing a "Circular Wastewater Management System" incorporating ZLD technologies. This system utilizes innovative methods of ZLD and multi-stage RO processes to maximize water recovery and minimize waste. We're committed to showcasing the cost-effectiveness of ZLD through this pilot program, paving the way for wider adoption across the industry.

Significant progress has been made in establishing key partnerships with potential partners to smoothly advance the best approach. Accordingly several discussions have been held with key stakeholders, including Solidaridad Bangladesh, Q.Stone Capital and Kingsley, as well as potential collaborators, TEAM Group and DBL Group.

Zero Liquid Discharge (ZLD) is a sophisticated water treatment process designed to completely eliminate liquid waste from industrial operations. By treating, recovering, and reusing all water within the system, ZLD ensures that no wastewater is released into the environment, leaving only solid waste for disposal or reuse.

The SMEP (Sustainable Manufacturing and Environmental Pollution) program , which funds pilot and research projects in Sub-Saharan Africa and South Asia, has selected Bangladesh’s textile sector for a ZLD project that will continue until September 2025. The project aims to create a sustainable, circular water management system for the textile industry. It will be funded transparently through a 1% consumer surcharge, ensuring financial transparency and accountability. The pilot ZLD system seeks to achieve up to 95% water savings and reuse, significantly reducing the environmental impact of the textile industry. Innovative technologies will play a crucial role in reducing the costs associated with implementing ZLD.

Bangladesh’s textile industry heavily relies on groundwater extraction and minimally treats wastewater before discharge, posing significant environmental challenges. Additionally, a lack of economic incentives has hindered investment in advanced ZLD systems. To address these issues, the project will demonstrate innovative technologies through the pilot ZLD system, showcase cost savings via a 1% consumer surcharge, and ensure long-term sustainability and operational transparency.

The ZLD system employs a multi-step process to treat and reuse wastewater within production. Key innovations include an efficient pretreatment system using electrocoagulation to extend the lifespan of ultrafiltration (UF) and reverse osmosis (RO) membranes. Multiple stages of RO will maximize treated water recovery and concentrate reject water, while advanced evaporation and crystallization processes will manage the RO reject. These innovations aim to enhance the efficiency and cost-effectiveness of the ZLD system.

The project’s overall benefits include up to

- 95% water savings and reuse,

- Reduced reliance on freshwater sources,

- Elimination of polluted water discharge,

- Increased resource efficiency, and

- The promotion of sustainable practices within the textile industry.

Funded by SMEP and executed by the Kingsley Engineering Service Corporation, this project aims to encourage to adopt sustainable practices by promoting water reuse, resource efficiency, and sustainability in our textile sector.

Kingsley Engineering Service Corporation is proud to be at the forefront of this transformative project. We believe ZLD technology holds the key to a more sustainable future for Bangladesh's textile industry. By demonstrating its effectiveness and cost-efficiency, we hope to encourage widespread adoption and pave the way to a new era of responsible manufacturing.

Reference:

- https://smepprogramme.org/project/zero-liquid-discharge-installation-for-purifying-and-reusing-up-to-95-of-textile-wastewater-at-key-bangladesh-suppliers/

- https://bmirror.net/bangladesh-textile-zero-liquid-discharge-zld/

Technology for a

Sustainable Future

Kingsley™ focuses on long term & sustainable future with a reliable technology.

You must be logged in to post a comment.