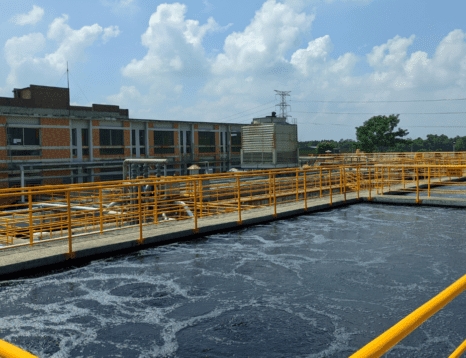

Kingsley Engineering Service Co. takes immense pride in announcing the successful completion of a prestigious project at KAI Aluminium Bangladesh Ltd. Kingsley team ensured top-notch solutions with seamless integration for the facility. Their scope included complete EPC for the ETP starting from design to installation of 25 m3/hr. Effluent Treatment Plant (ETP).

An Industry Leader

KAI Bangladesh Aluminium Ltd.

KAI Bangladesh Aluminium Ltd. stands as a well-known and widely recognized entity in the industry, serving as a prominent importer, supplier, distributor, fabricator, wholesaler, retailer, and manufacturer of aluminum products within the Bangladeshi market. Situated at 110, Khortoli, Sataish Road, Tongi, Gazipur, the company's modern and advanced factory embodies a commitment to excellence in the production and provision of high-quality aluminum solutions. Renowned for its comprehensive range of products and services, KAI Bangladesh Aluminium Ltd. is dedicated to meet the diverse needs of its clientele with a focus on professionalism, innovation, and unwavering adherence to the highest industry standards. Besides their well-organized production cycle, they are also committed to secure the environment by following the legislative requirements. Following this commitment, KAI Bangladesh Aluminium Ltd. awarded the 600 KLD Effluent Treatment Plant Project to Kingsley, a well-known figure in the field of wastewater engineering in Bangladesh.

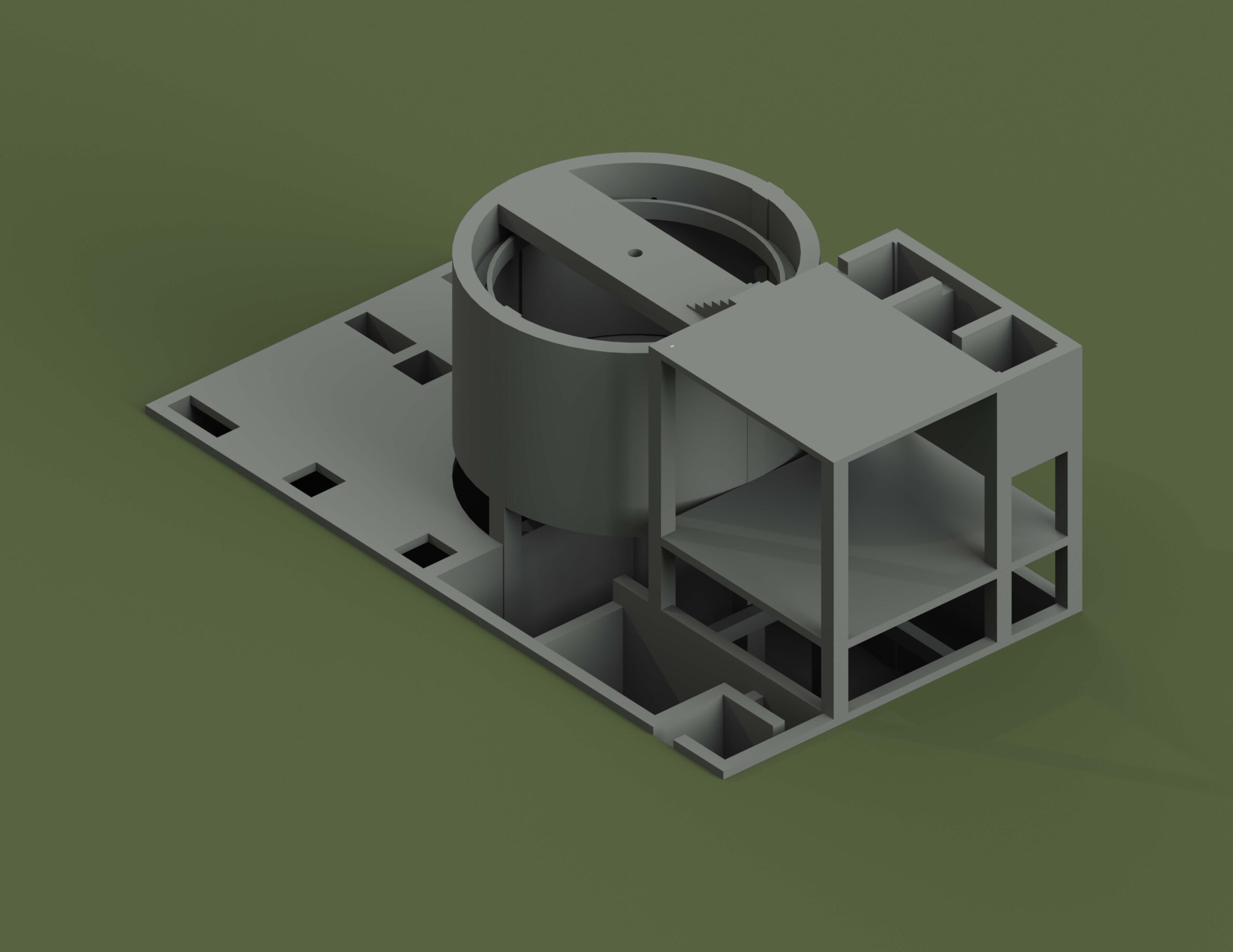

Advanced

Treatment Techniques of Kingsley

Kingsley prioritizes sustainable and responsible practices through the application of advanced physio-chemical treatment techniques in their Effluent Treatment Plant, effectively mitigation of the environmental impact of their industrial processes. ETP at KAI Aluminium Bangladesh Ltd. involves a comprehensive process to efficiently manage and treat industrial wastewater. This treatment method integrates both physical and chemical processes to remove contaminants from the effluent generated during aluminum production. Physical processes, such as sedimentation and filtration, are employed to separate solid particles from the wastewater. Simultaneously, chemical treatments, including coagulation and flocculation, are applied to induce the aggregation of finer particles, facilitating their easier removal. Additionally, pH adjustment and the use of specific chemical agents contribute to the neutralization and precipitation of pollutants, ensuring compliance with environmental regulations.

Co-Operative

Approach

Throughout the project, Kingsley maintained a collaborative approach, working closely with the team of KAI Aluminium to understand their specific requirements & delivered tailor-made solutions. Emphasizing safety and quality, the team of experts guaranteed that all installations adhered to industry-leading standards. Rigorous quality control measures were implemented, guaranteeing reliable operation of critical processes. Kingsley is committed to supporting the local economy through strategic sourcing of materials from both foreign and local markets.

Kingsley Engineering Service Co. extends its gratitude to the entire team involved in the project, including the partners at KAI Aluminium Bangladesh Ltd., for their collaboration and trust. The successful completion of this project further cements Kingsley’s position as a leading provider of environmental solutions, dedicated to driving growth and prosperity for industries and communities alike.

Technology for a

Sustainable Future

Kingsley™ focuses on long term & sustainable future with a reliable technology.

You must be logged in to post a comment.