Kingsley Engineering Service Co. has been selected to build a cutting-edge wastewater treatment facility for RRP Pharmaceuticals in Bangladesh. This project demonstrates the pharmaceutical industry's growing commitment to environmental protection. The new facility will comply with strict government regulations, including the Department of Environment's guidelines and the ECR 2023 framework.

Effluent Treatment Plant for

RRP Pharmaceuticals Ltd.

RRP Pharmaceuticals Ltd., the RRP Group's flagship company, is a major player in Bangladesh's rapidly growing veterinary pharmaceutical business. The company, based in Soraikandi, Ishwardi, Pabna, manufactures crucial veterinary medicines that play an important role in animal health and illness prevention.

Beyond its status as a pharmaceutical industry pioneer, RRP Pharmaceuticals is highly committed to sustainable practices. This focus is obvious in their work with Kingsley Engineering Service Corporation to install an advanced ETP with a Fenton Reagent process, which is a cutting-edge wastewater treatment technique.

The Importance of

Sustainable Water Treatment

Water is essential in pharmaceutical manufacture, but incorrect wastewater management creates a serious environmental concern. Pharmaceutical manufacture produces effluents comprising medication residues and manufacturing byproducts, which can harm aquatic life and pollute water bodies. RRP Pharmaceutical Ltd.'s Effluent Treatment Plant is a pioneering endeavor that addresses this issue. By properly treating wastewater, the plant protects the environment, conserves water resources, and contributes to global sustainability goals. This study highlights the importance of innovation and experience in reducing environmental effect and guaranteeing responsible pharmaceutical production.

Kingsley’s

Innovative Solution

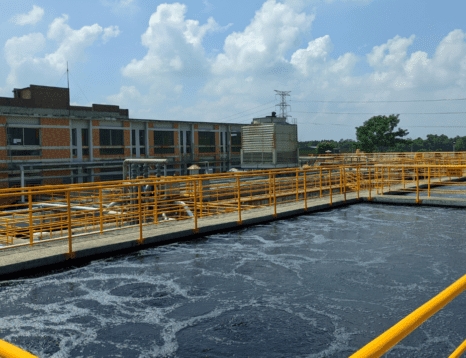

Kingsley Engineering prioritizes environmental responsibility by implementing a state-of-the-art Effluent Treatment Plant (ETP) at RRP Pharmaceuticals Ltd. In this advanced system, a multi-stage approach will be implemented to effectively manage and treat industrial wastewater generated during animal health pharmaceutical production.

The comprehensive treatment process combines physical, chemical, and biological techniques to remove contaminants from the wastewater. In the initial stage, physical processes like sedimentation and filtration remove larger solid particles. Following this, chemical treatments such as coagulation and flocculation work together to clump smaller particles, making them easier to separate. Additionally, adjustments are made to the wastewater's pH, and specific chemicals are introduced to neutralize and precipitate pollutants, ensuring compliance with environmental regulations.

Co-Operative

Approach

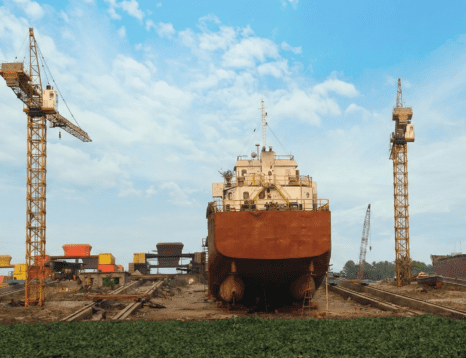

Throughout the project, Kingsley has been maintaining a collaborative approach, working closely with the team of RRP Pharmaceuticals to understand their specific requirements & delivered tailor-made solutions. Emphasizing safety and quality, the team of experts guaranteed that all installations adhered to industry-leading standards. Rigorous quality control measures were implemented, guaranteeing reliable operation of critical processes. Kingsley is committed to supporting the local economy through strategic sourcing of materials from both foreign and local markets.

Challenges Faced by

Kingsley in ETP Construction

- The effluent from the pharmaceutical plant had a distinct makeup, unlike those seen in similar operations. Because the plant was under construction, real effluent parameters were unavailable. Kingsley Engineering used wastewater parameter predictions based on previous experience with similar pharmaceutical projects.

- Initial wastewater contamination levels were estimated using historical data from past pharmaceutical operations (COD, BOD, TDS, and TSS). This presented difficulties in developing a cost-effective ETP capable of meeting severe DoE criteria.

- Kingsley decided to use the intricate chemical treatment procedure known as the Fenton reagent technique to deal with the expectedly high levels of contamination. The method's implementation and management increased the project's complexity.

- Poor soil conditions and water infiltration caused challenges throughout the civil construction phase of the ETP. The design has to be adjusted by the engineering team to account for these site-specific difficulties and avoid project delays.

Finally, Kingsley has always endeavored to take challenges for treating different types of wastewater and this ETP is going the be another milestone. The team is optimistic about a successful and flagship project in due time.

Technology for a

Sustainable Future

Kingsley™ focuses on long term & sustainable future with a reliable technology.

You must be logged in to post a comment.