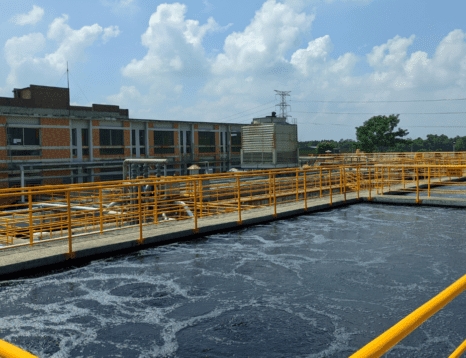

Kingsley Engineering Service Co. was entrusted with the commissioning of the Effluent Treatment Plant (ETP) at ALTECH Aluminium Industries Ltd. (Unit-2). The ETP, with a capacity of 30 m3/hr (720 m3/day), stands as a testament to ALTECH's commitment to environmental stewardship and compliance.

Altech Aluminium Industries (Unit-2) Ltd. is an Aluminum processing factory which manufactures Aluminum located at Bhurulia, Gazipur Sadar, Gazipur. In a significant milestone for environmental sustainability in Bangladesh, ALTECH Aluminium Industries Ltd. pioneered the establishment of the country's first state-of-the-art extrusion and anodized aluminum products manufacturing facility in the year 2000. Specializing in the production of high-quality aluminum products, ALTECH has played a pivotal role in various sectors, including construction, power, automobiles, and decoration, contributing to the country's industrial and infrastructural development.

ALTECH Aluminium Industries

adopts Physio-Chemical Treatment for Sustainable Effluent Management

By integrating Physio-Chemical Treatment technology into the ETP, ALTECH Aluminium Industries Ltd. ensures that the effluent generated during its manufacturing processes undergoes a thorough and environmentally responsible treatment. This commitment aligns with broader industry trends that emphasize sustainable and eco-friendly practices, reinforcing ALTECH's position as an industry leader in responsible manufacturing.

The successful commissioning of the Effluent Treatment Plant at ALTECH Aluminium Industries Ltd. (Unit-2) signifies a collaborative effort between ALTECH and Kingsley Engineering Service Corporation to uphold environmental standards and promote sustainable industrial practices in Bangladesh. The adoption of Physio-Chemical Treatment technology reflects a commitment to effective wastewater treatment, ensuring that ALTECH continues to contribute to the nation's industrial growth while minimizing its environmental footprint.

Kingsley's Journey in implementing

ETP Project with Precision and Responsibility

The journey toward completing the ETP project commenced on September 25, 2019, with the awarding of the work order for ETP electro-mechanical items' supply and the acquisition of the Environmental Clearance Certificate (ECC) from the Department of Environment (DoE). This marked a crucial step in ensuring that the project aligns with environmental regulations and standards. Subsequently, the ETP work officially commenced on November 7, 2020, reflecting a meticulous planning and execution timeline.

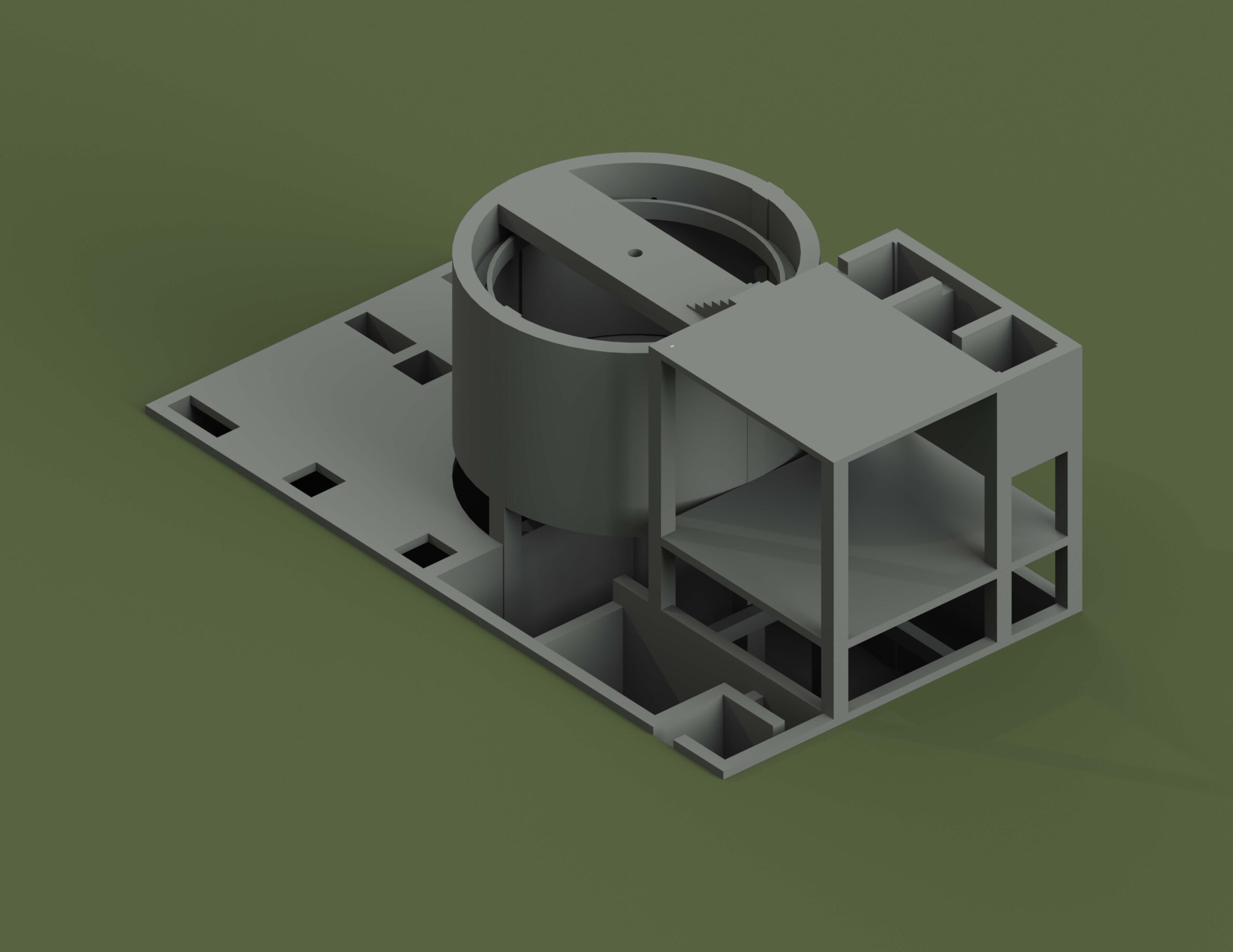

The utilization of Physio-Chemical Treatment technology in the effluent treatment process underscores the sophisticated and environmentally conscious approach adopted for the project. Physio-Chemical Treatment involves a combination of physical and chemical processes to effectively treat industrial wastewater. This approach facilitates the removal of contaminants through various mechanisms such as coagulation, flocculation, sedimentation, and chemical precipitation.

The successful completion of the ETP project was officially recognized with the issuance of the "Project Completion Certificate" by ALTECH authorities. This certificate not only signifies the culmination of the project but also acknowledges Kingsley Engineering Service Corporation's expertise and dedication in delivering a fully functional and compliant Effluent Treatment Plant.

On 25 September 2019, the work order was awarded for ETP electro-mechanical items' supply & ECC (Environmental Clearance Certificate) from DoE. ETP work commencement date was 7th November 2020. Afterwards, the “Project Completion Certificate” from was received the Altech authority for the successful completion and handover of the project. To refer, Physico-Chemical Treatment technology was used for the effluent treatment.

Technology for a

Sustainable Future

Kingsley™ focuses on long term & sustainable future with a reliable technology.

You must be logged in to post a comment.