Project

Description

Kingsley Engineering Service Corporation has completed Common Effluent Treatment Plant at Abdul Monem ltd., Igloo Dairy Ltd. & Igloo Foods Ltd. with the purpose of treating effluent water generated by the Abdul Monem Ltd. (Igloo Ice Cream), Igloo Dairy Ltd & Igloo Foods Ltd. factory. This is a CETP since effluent from three factories are being treated in a single ETP.

Project

Background

The Food, Ice cream and Dairy industry involve mixing ingredients, pasteurization, homogenization, aging, churning/freezing, and packaging. This process generates significant wastewater. IGLOO's specific volume depends on production scale, but expects high level of organic matter (milk, fruit), fats, oils, and grease from the product itself. Cleaning chemicals and sugar residues add to the wastewater load, requiring proper treatment for environmental compliance.

The CETP

Key Features

Key

Challenges

- DoE Compliance: To comply with Bangladesh's Department of Environment (DoE) standards for wastewater discharge.

- Wastewater Drainage Issue: Cleaning chemicals, sanitizers, and acids/bases used for washing equipment add complexity to the wastewater stream, requiring special treatment considerations.

- High COD in Wastewater: The IGLOO ice cream factory's wastewater contains way too much organic matter. On average, there's 13,600 mg/L of Chemical Oxygen Demand (COD) in their wastewater. That's significantly higher than the limit set by the Department of Environment (DoE) which is only 200 mg/L.

- Chemical Treatment: Cleaning chemicals, sanitizers, and acids/bases used for washing equipment add complexity to the wastewater stream, requiring special treatment considerations.

- Biological Treatment Difficulties: Sugar residues from syrups and ingredients add to the organic load and can interfere with some biological treatment methods.

- Variation in Wastewater: Food factories often produce diverse products, leading to fluctuating wastewater compositions that can challenge treatment consistency.

Solutions

Kingsley implemented a Biological Anaerobic (UASB) & Aerobic Treatment Process to address the challenges. The reasons of choosing this technology are the following-

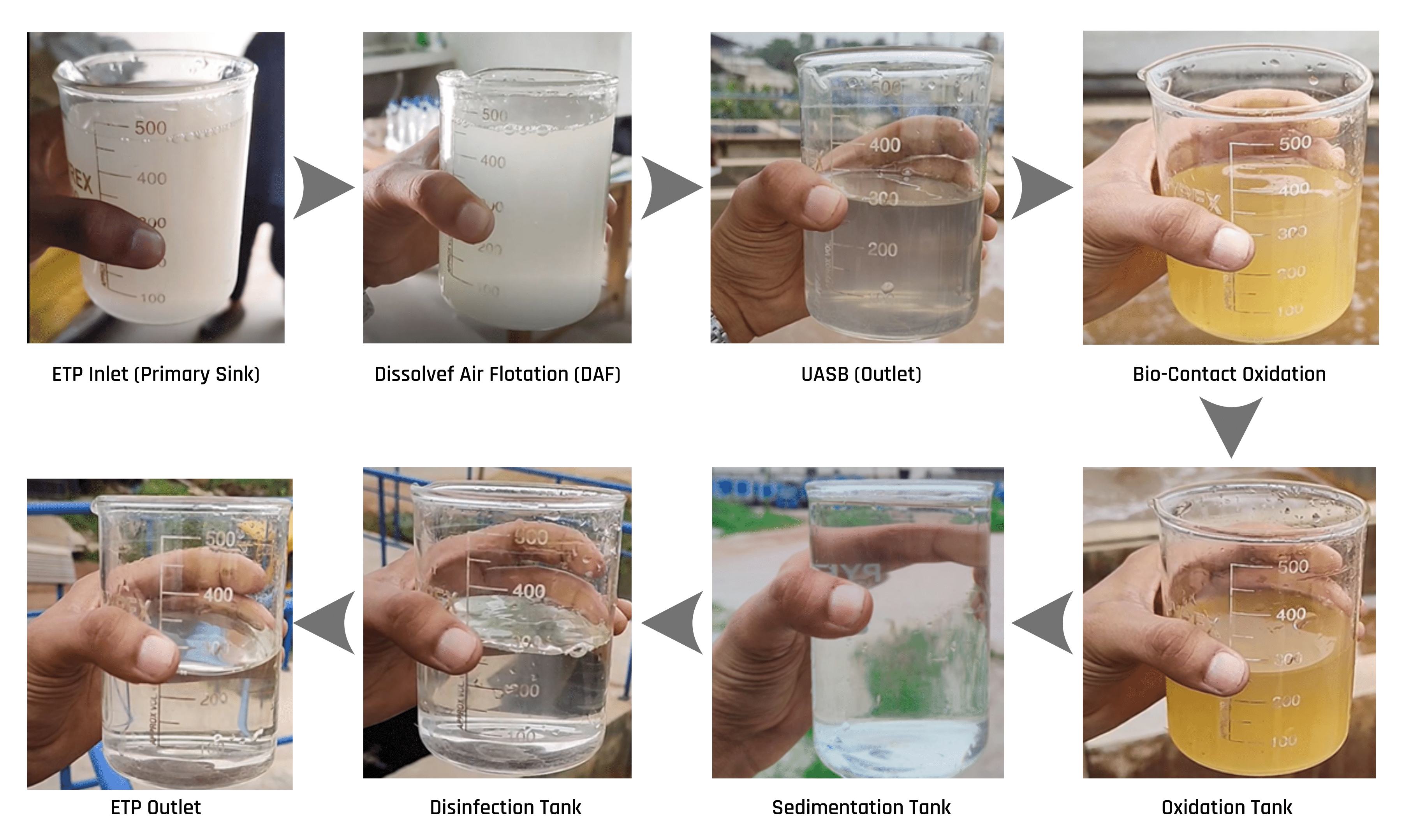

- DAF (Dissolved Air Floatation): DAF is installed for removing contaminants such as fats, oils, suspended solids, and organic matter. As a result, COD is significantly reduced.

- UASB Powerhouse: The UASB stage excels at breaking down organic matter, a major component of food industry wastewater. This includes high concentrations of carbohydrates, proteins, and fats originating from the wastewater.

- Aerobic Polish: Following the UASB, the aerobic treatment process further polishes the effluent by removing any remaining organic matter that may have escaped the UASB stage. This two-stage approach ensures a high level of organic matter removal, leading to cleaner effluent.

- Cost-Effectiveness: The anaerobic nature of the UASB stage doesn't require oxygen for treatment, reducing energy consumption compared to solely aerobic processes. This translates to potential cost savings for food industries.

- Improved Sludge Management: The UASB process generates a specific type of sludge with good settling characteristics, simplifying sludge management compared to some other biological treatment methods.

- Flexibility and Adaptability: Food production often involves seasonal variations and diverse product lines. The UASB-aerobic combination can handle these fluctuations in organic matter content and wastewater composition more effectively compared to some single-stage treatment processes.

- Reduced Discharge Concerns: The high-quality effluent produced by this two-stage treatment meets stricter discharge standards, minimizing concerns about environmental impact.

- Potential for Reuse: In some cases, the treated effluent might even be suitable for certain non-potable reuse applications within the food industry, potentially reducing reliance on freshwater resources.

Kingsley provided its visionary solution by choosing Common Effluent Treatment Plant, keeping in mind the client’s requirement and environmental safety.

Main Characteristics of Common Effluent Treatment Plant (CETP)

- Treats wastewater from diverse industries in an industrial zone.

- Aims for compliance with environmental regulations or potential reuse.

- Treats wastewater through stages: solid removal, biological breakdown, clarification, optional disinfection, discharge/reuse.

- Participating industries share responsibility for operating and maintaining the CETP, including cost-sharing for treatment, infrastructure, personnel.

- Offers effective solution for industries, sharing costs and responsibilities for operation and maintenance.

Project

Benefits

The successful implementation of the CETP at the Abdul Monem Group has resulted in several significant benefits:

- Reduced environmental impact

- Compliance with regulations

- Sustainable operations

- Improved resource utilization

- Cost Savings

Kingsley’s

Achievement

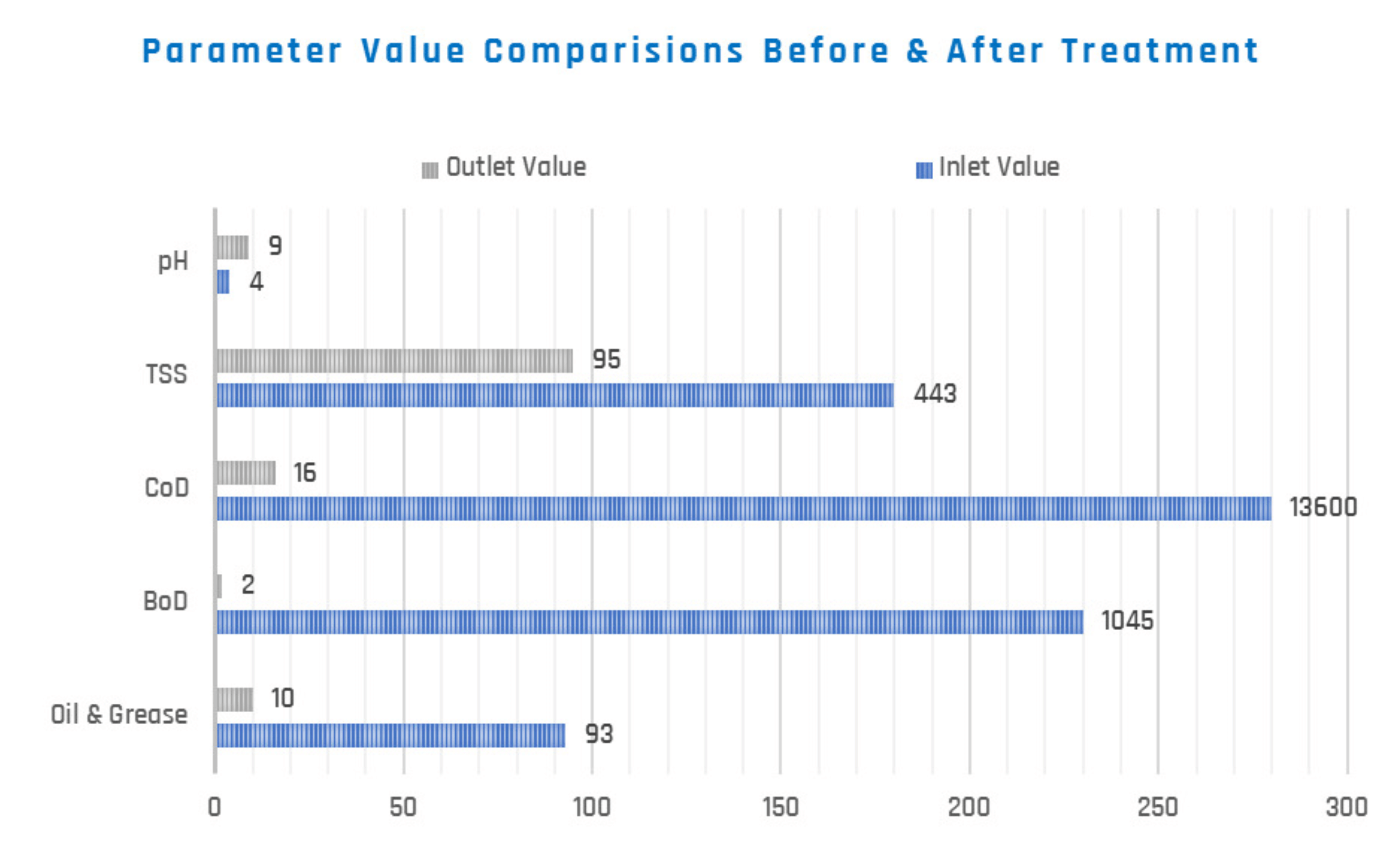

Achieved outstandingly low COD, BOD, Oil & Grease and TSS outlet values, reflecting exceptional wastewater treatment efficacy.

- BOD reduced by 99%

- COD reduced by 99%

- TSS reduced by 79%

- Oil & Grease reduced by 89%

Reduction chart of pollutants (Inlet vs Outlet)

CETP

Performance

Treatment performance at different stages of the CETP

Conclusion

The IGLOO Ice Cream Factory CETP project stands as a shining example of CETP technology's effective utilization in treating industrial wastewater. CETP's proficiency in planning, building, and initiating guaranteed the project's punctual execution and smooth functioning. This facility holds significant importance in safeguarding the environment and advocating for sustainable initiatives within the IGLOO Ice Cream Factory premises.

Technology for a

Sustainable Future

Kingsley™ focuses on long term & sustainable future with a reliable technology.

You must be logged in to post a comment.