Project

Description

Kingsley Engineering Service Corporation has implemented a project for the construction of onsite sewage treatment facilities at Bangladesh Garment Manufacturers and Exporters Association (BGMEA) Complex with the purpose of treating the sewage water of process to be generated by the domestic use (Commode Flush).

Project

Scope

- Detailed design and engineering

- Preparation of civil and equipment drawings

- Manufacturing and supply of all required mechanical equipment

- Installation and commissioning of the plant

- Providing a comprehensive operation and maintenance manual

The STP

Key Features

Key

Challenges

- Meeting stringent effluent discharge standards.

- The BGMEA complex authority required an STP that could effectively treat wastewater to comply with Bangladesh's Department of Environment (DoE) standards for wastewater discharge.

- The project site had very limited space available for the STP installation.

- One of the biggest challenges was to make the water re-usable for gardening, cleaning and car washing.

Solutions

Kingsley implemented a Membrane Bio-Reactor (MBR) technology-based STP. The reasons of choosing MBR are the following-

- MBR is a proven and advanced wastewater treatment process that combines biological treatment with membrane filtration to produce high-quality effluent. (Solution to Challenge no. 1 & 2)

- In contrast to conventional Activated Sludge Process (ASP), MBR technology ensures remarkable space efficiency owing to its cutting-edge features and streamlined design. Also, KESC provided integrated sewage treatment module in order to save space and to reduce civil works’ cost. (Solution to Challenge no. 3)

- MBR serves high quality treatment, so minimal disinfection is needed. Even then, UV sterilizer was introduced to reduce any harmful substances. (Solution to Challenge no. 4)

Kingsley provided its visionary solution by choosing Integrated Sewage Treatment Plant, keeping in mind the client’s requirement and environmental safety.

Main Characteristics of Integrated Sewage Treatment Plant

- Space Saving & Long Lifetime

- Good Effect of Pollution Removal

- Less Production of Sludge

- Good Deodorizing Effect & Low Noise

Exclusive

Features of MBR

- Smaller footprint

-

- Large clarifiers are rendered obsolete, replaced by smaller, rectangular-shaped chambers housing membrane cassettes.

- Higher biomass concentrations within bioreactors allow for the storage of the same total mass of solids in a smaller tank.

- The smaller footprint of the system result in up to a 50% reduction in space requirements compared to traditional methods.

- High-quality effluent, free of bacteria and pathogens

-

- Effluent from the MBR process is devoid of suspended solids and exhibits reduced bacterial and viral content.

- Due to its high quality, minimal disinfection is required before discharge.

- Treated effluent from the MBR process is also suitable for direct feeding into a reverse osmosis (RO) process.

- Higher automation capabilities

Project

Benefits

The successful implementation of the MBR STP at the BGMEA complex has resulted in several significant benefits:

- Reduced environmental impact

- Compliance with regulations

- Sustainable operations

Kingsley’s

Achievement

- Completion of the project within a remarkable timeframe of 1.5 years.

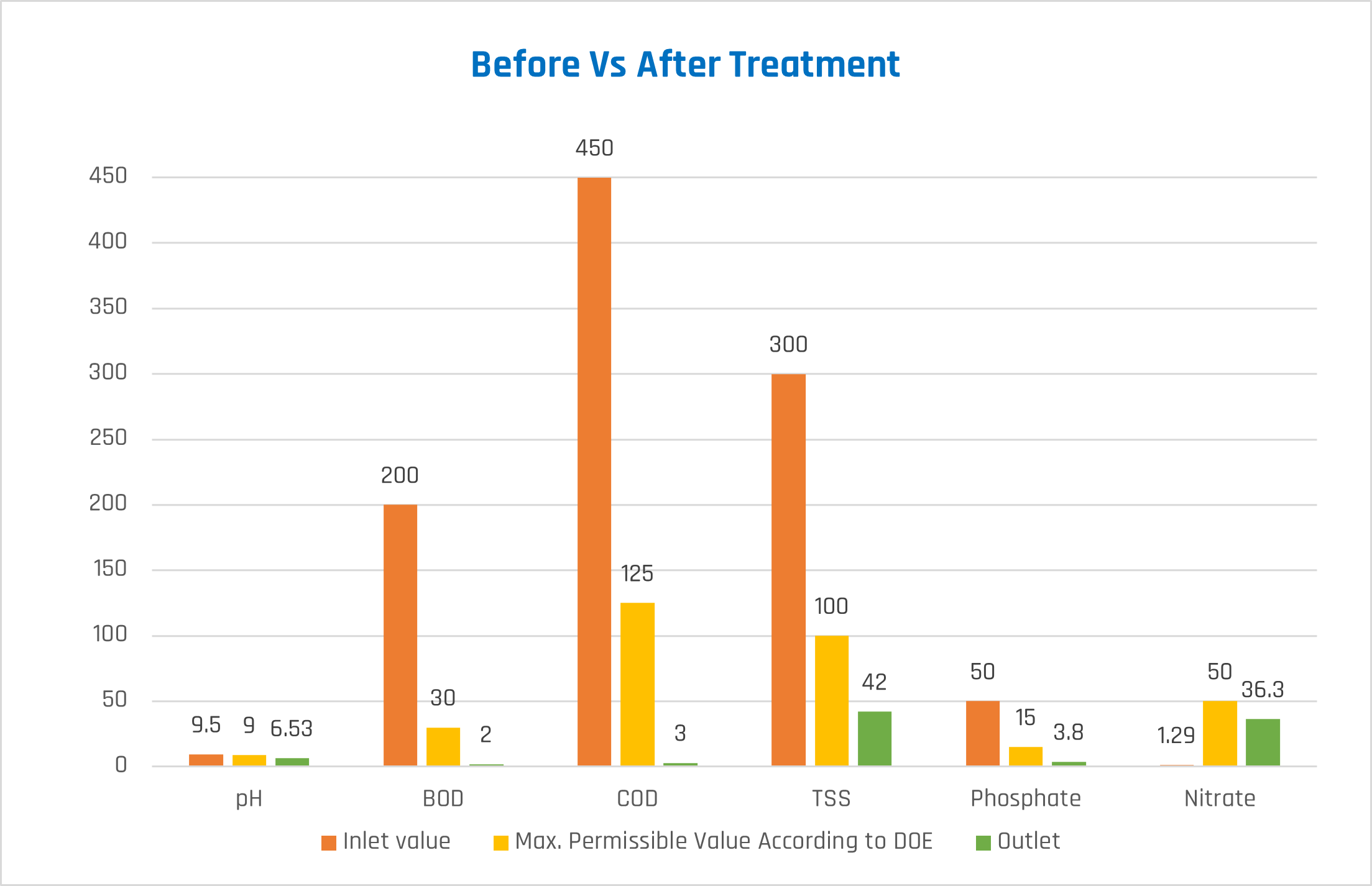

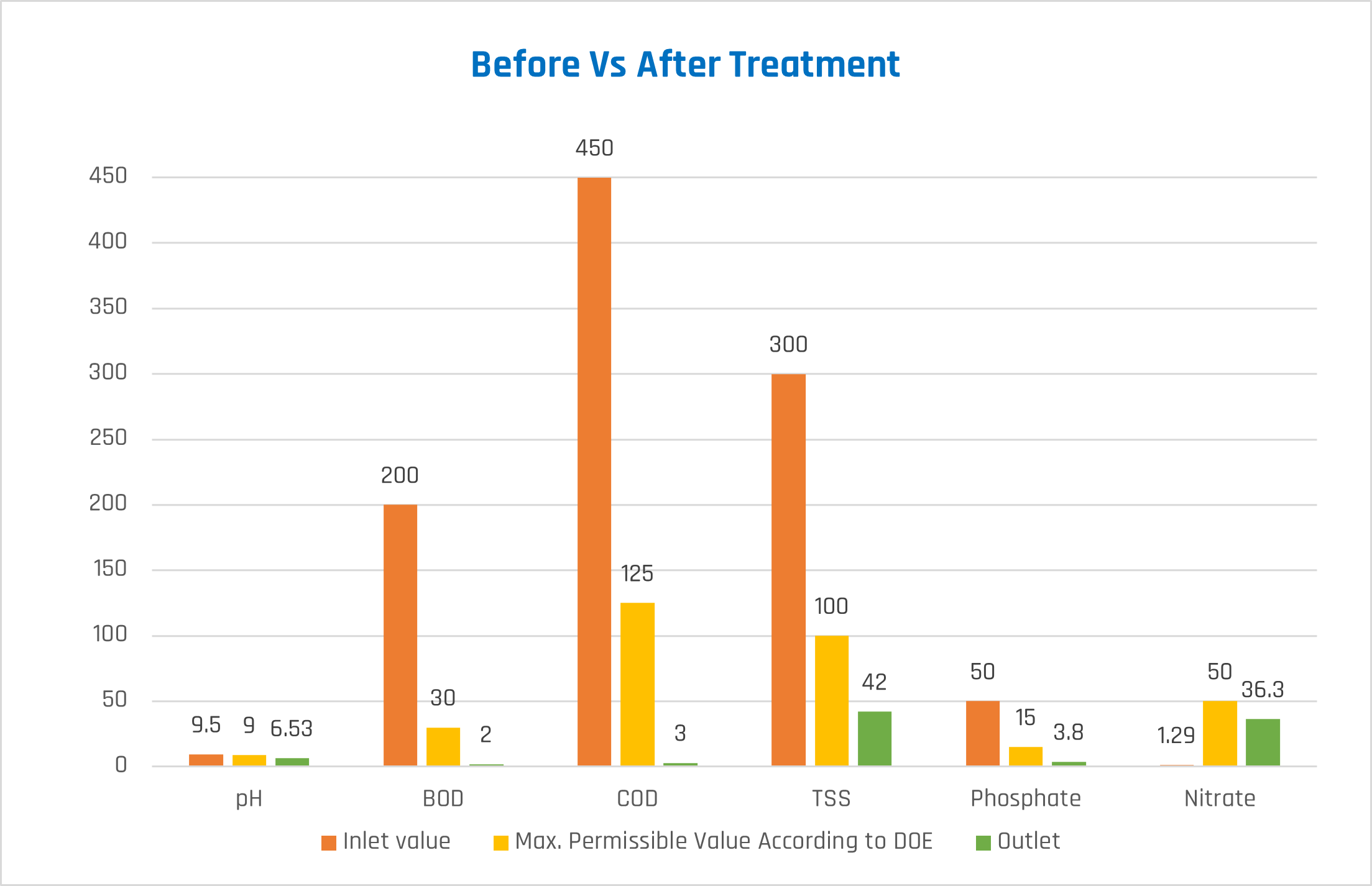

- Achieved outstandingly low COD and BOD outlet values, reflecting exceptional wastewater treatment efficacy.

- Complete absence of coliform detection, indicating the high level of sanitation and disinfection achieved by the project team.

- Implementation of environmentally friendly practices, including grass turfing over the Integrated Sewage Treatment Plant (ISTP) module, enhancing the aesthetic appeal of the project site.

Comparison of Parameters during Before & After Treatment

Operating Cost

Our Sewage Treatment Plant (STP) is cost-effective due to its chemical-free design. Electricity is the primary expense. The operating cost of this STP is-

- 5~7.5 Tk per cubic meter (0.0065~0.0075 Tk/liter)

Conclusion

The BGMEA Complex Sewage Treatment Plant project is a successful example of MBR technology's application in treating industrial wastewater. KESC's expertise in design, construction, and commissioning ensured the project's timely completion and successful operation. The plant plays a vital role in protecting the environment and promoting sustainable practices within the BGMEA complex.

Technology for a

Sustainable Future

Kingsley™ focuses on long term & sustainable future with a reliable technology.

You must be logged in to post a comment.