Project

Description

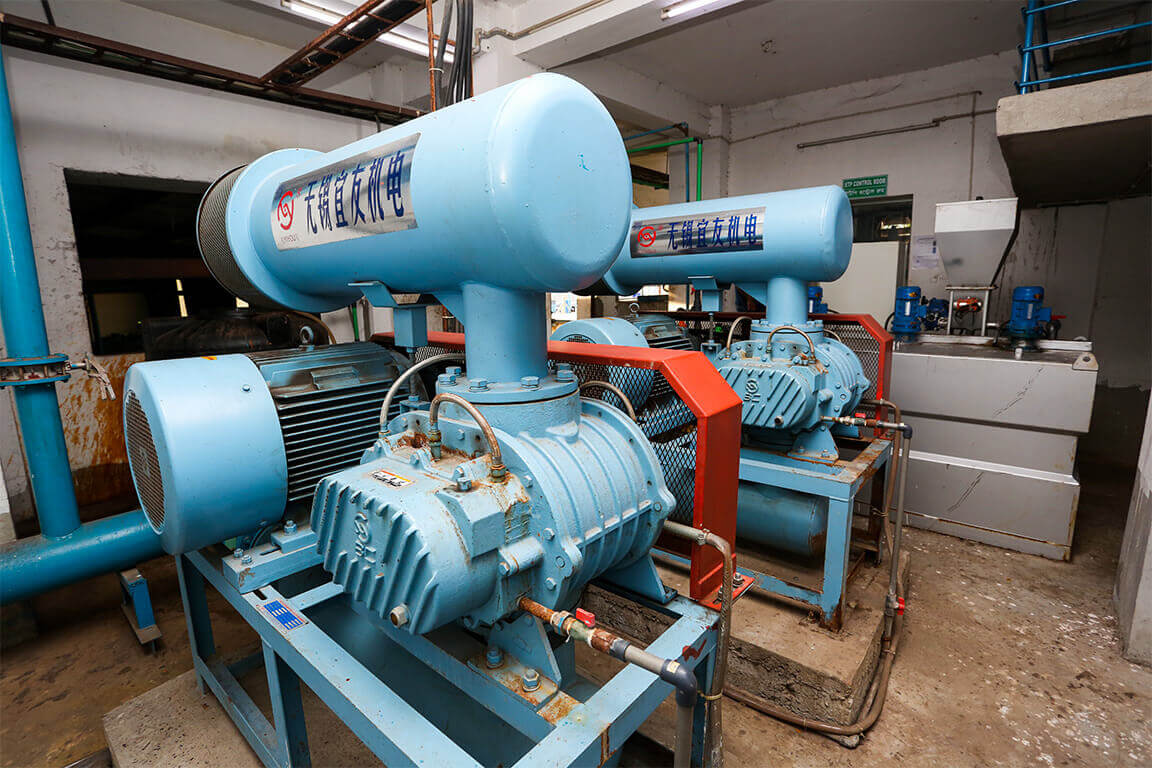

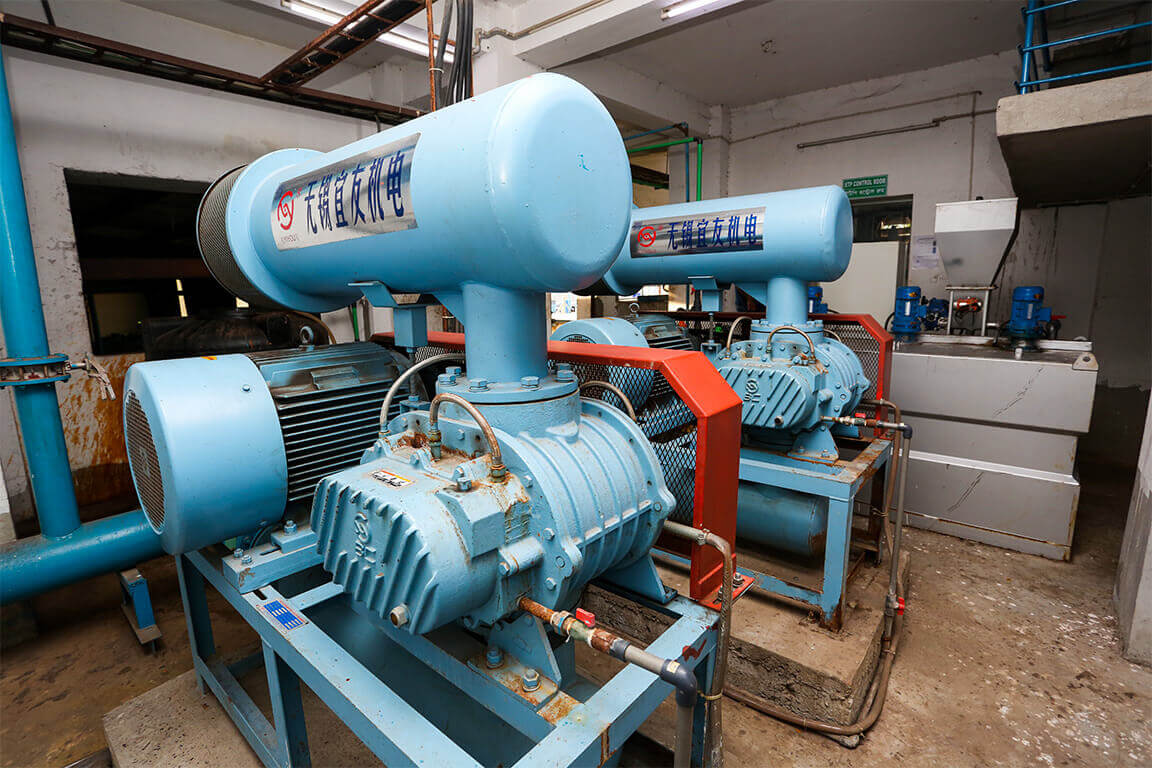

Kingsley Engineering Service Corporation employed a Moving Bed Biofilm Reactor (MBBR) system to construct effluent treatment facilities at Ripon Knitwear Ltd. This advanced technology effectively treats wastewater generated during the manufacturing process.

Project

Scope

KINGSLEY™ scope of work for this project included:

- Detailed design and engineering of the effluent treatment facilities.

- Preparation of civil and equipment drawings

- Manufacturing and supply of all required mechanical equipment

- Installation and commissioning of the plant

- Providing a comprehensive operation and maintenance manual

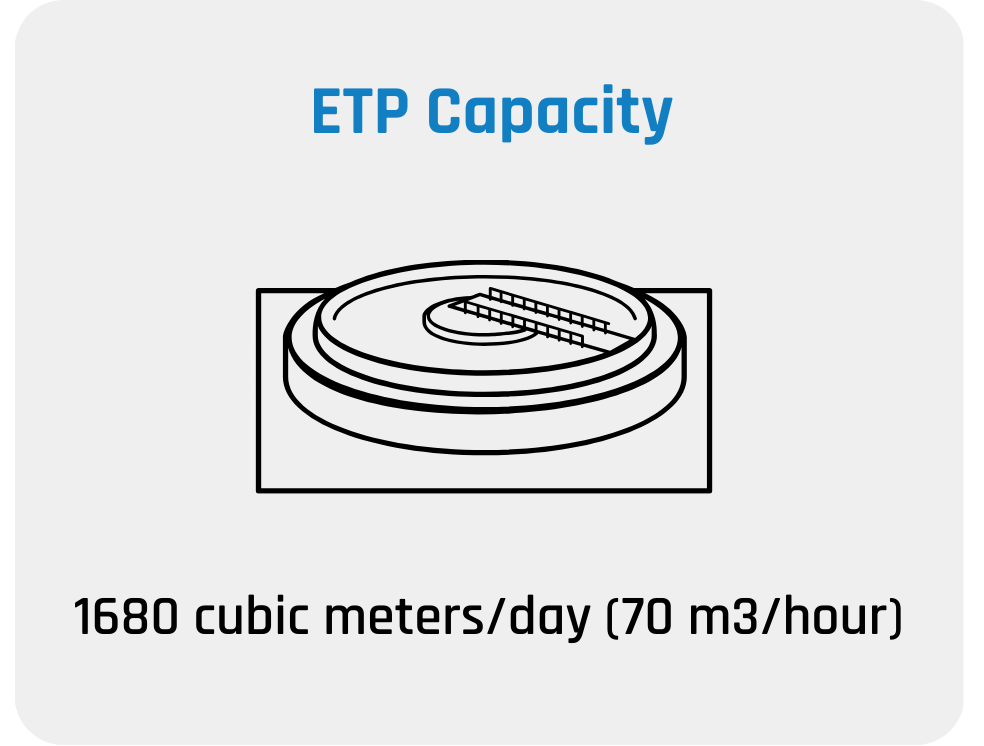

The ETP

Key Features

Key

Challenges

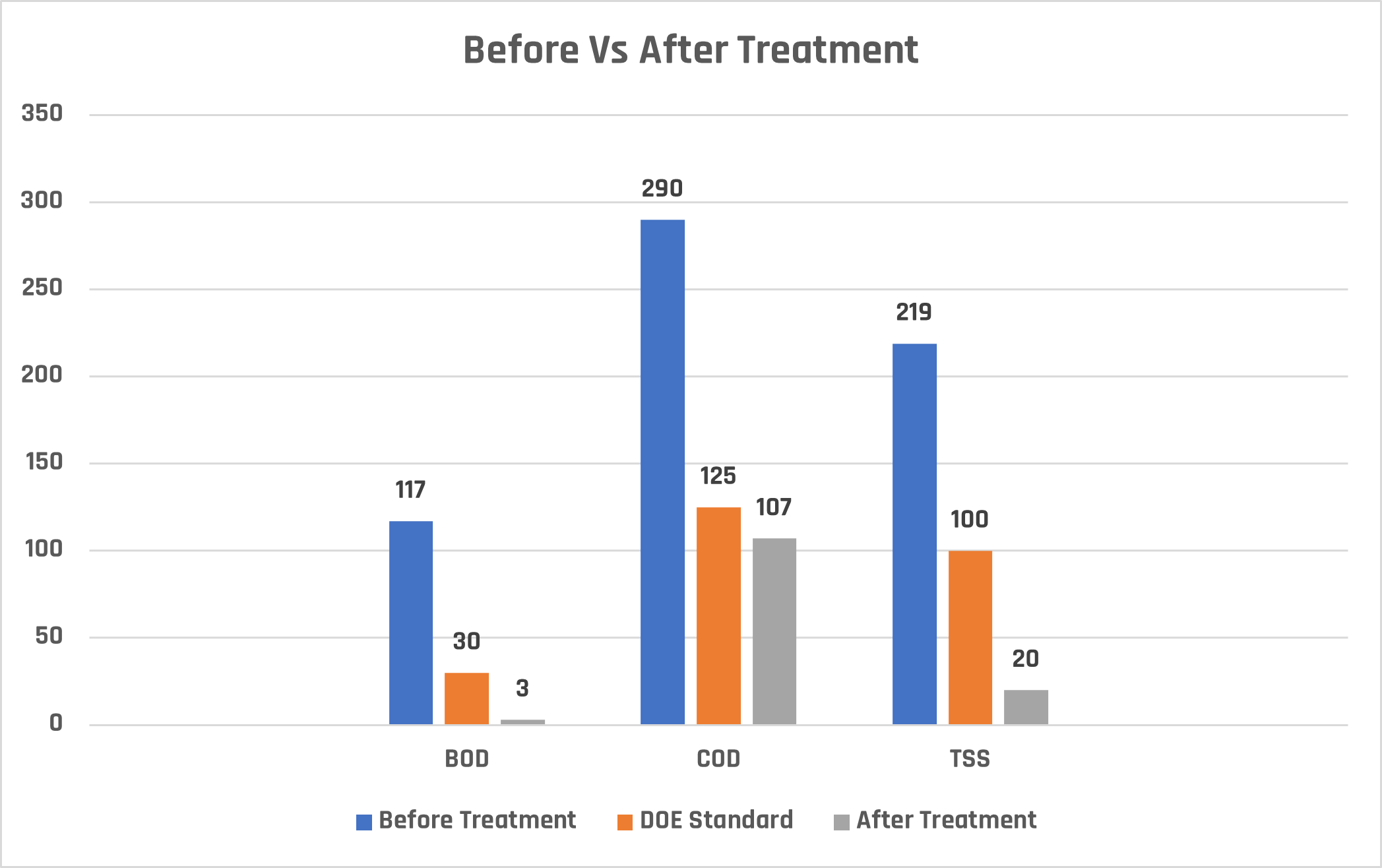

- Meeting stringent effluent discharge standards.

- The Ripon Knitwear Ltd. required an ETP that could effectively treat wastewater to comply with Bangladesh's Department of Environment (DoE) standards for wastewater discharge.

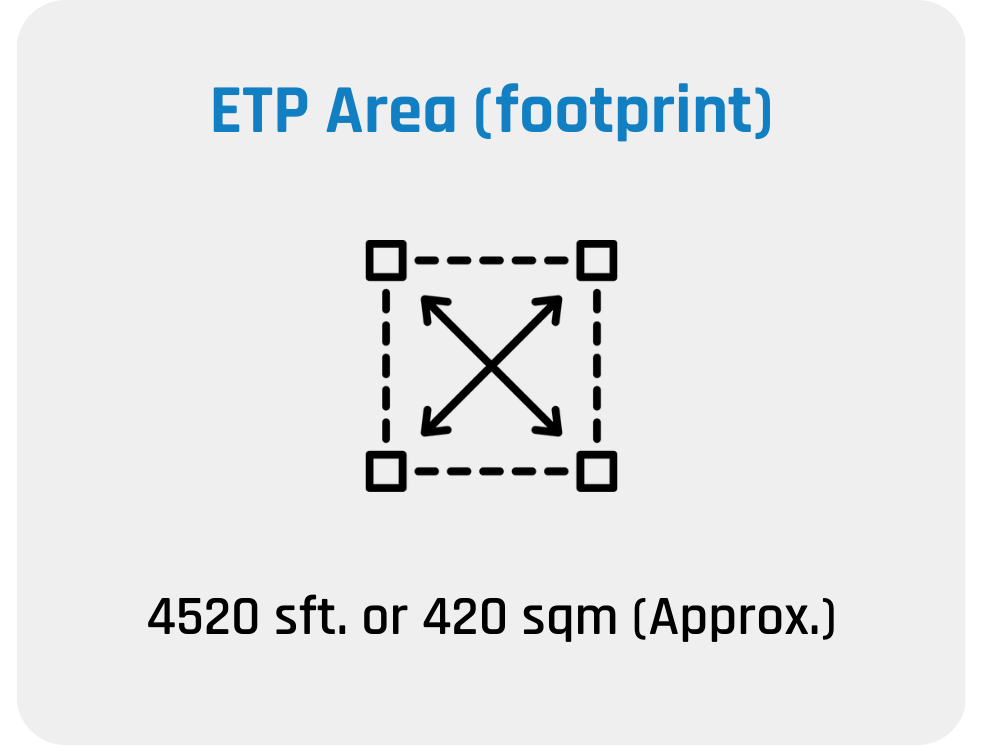

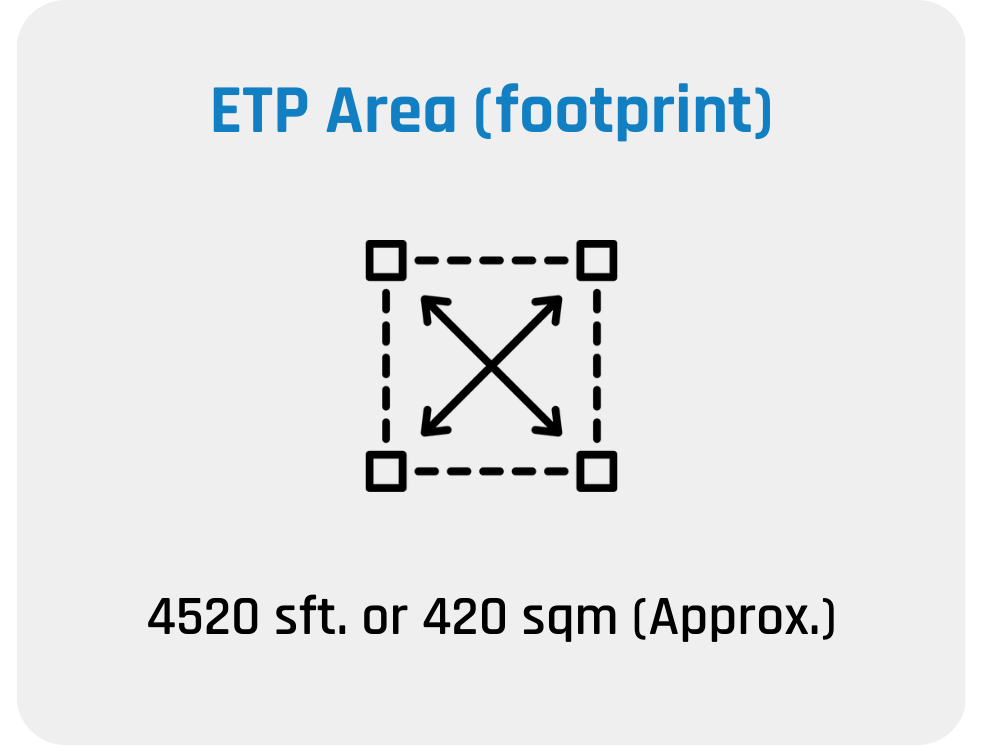

- The project site had very limited space available for the ETP installation.

- One of the biggest challenges was to make the water re-usable for gardening, cleaning and car washing.

Solutions

KINGSLEY™ implemented a Moving Bed Biofilm Reactor (MBBR) technology-based ETP to address the challenges. The reasons for choosing MBBR are the following-

- MBBR performs well under stringent effluent regulations because of its high surface media. As a result of the media's continuous mixing with wastewater and pollution-breaking properties, a supercharged bio-cleaning zone is created. For total compliance, the system can also be tailored to address particular contaminants like nitrogen. (Solution for problem no. 1 & 2)

- Unlike ASP (activated sludge process) needing large settling tanks, MBBR uses special filters with high surface area. This packs more cleaning power into a smaller space, making MBBR ideal for limited areas and also reducing civil works’ costs. (Solution for problem no. 3)

- With its high-capacity biofiltration, MBBR successfully tackles reuse issues. The large surface area promotes better bacterial development, which effectively breaks out pollutants. Furthermore, the system may be adjusted to target particular contaminants, guaranteeing that treated water is suitable for cleaning, car washing, and irrigation. (Solution for problem no. 4)

Kingsley provided its visionary solution by choosing MBBR Treatment Plant, keeping in mind the client’s requirements and environmental safety.

Main Characteristics of MBBR Treatment Plant

- Biofilm carriers

- High treatment efficiency

- Compact design

- Flexible treatment

Exclusive Features of

MBBR (Moving Bed Biofilm Reactor)

- Economic Efficiency: MBBR's compact design necessitates a lower initial capital expenditure compared to conventional treatment systems. Additionally, the reduced need for maintenance contributes to lower life-cycle costs.

- Superior Effluent Quality: The extensive surface area provided by the biofilm carriers fosters a robust microbial population, enabling comprehensive biodegradation of pollutants and resulting in high-quality effluent.

- Assured Regulatory Compliance: The inherent adaptability of the MBBR system allows for targeted treatment of specific pollutants. This ensures consistent compliance with even the most stringent discharge regulations of ZDHC and DoE.

- Energy Optimization: The continuous movement of the media within the MBBR tank fosters efficient mixing, thereby minimizing aeration requirements and reducing overall energy consumption.

- Simplified Operation: The straightforward design of the MBBR system, with minimal moving parts, minimizes operational complexity and facilitates ease of use.

Project

Benefits & Performance

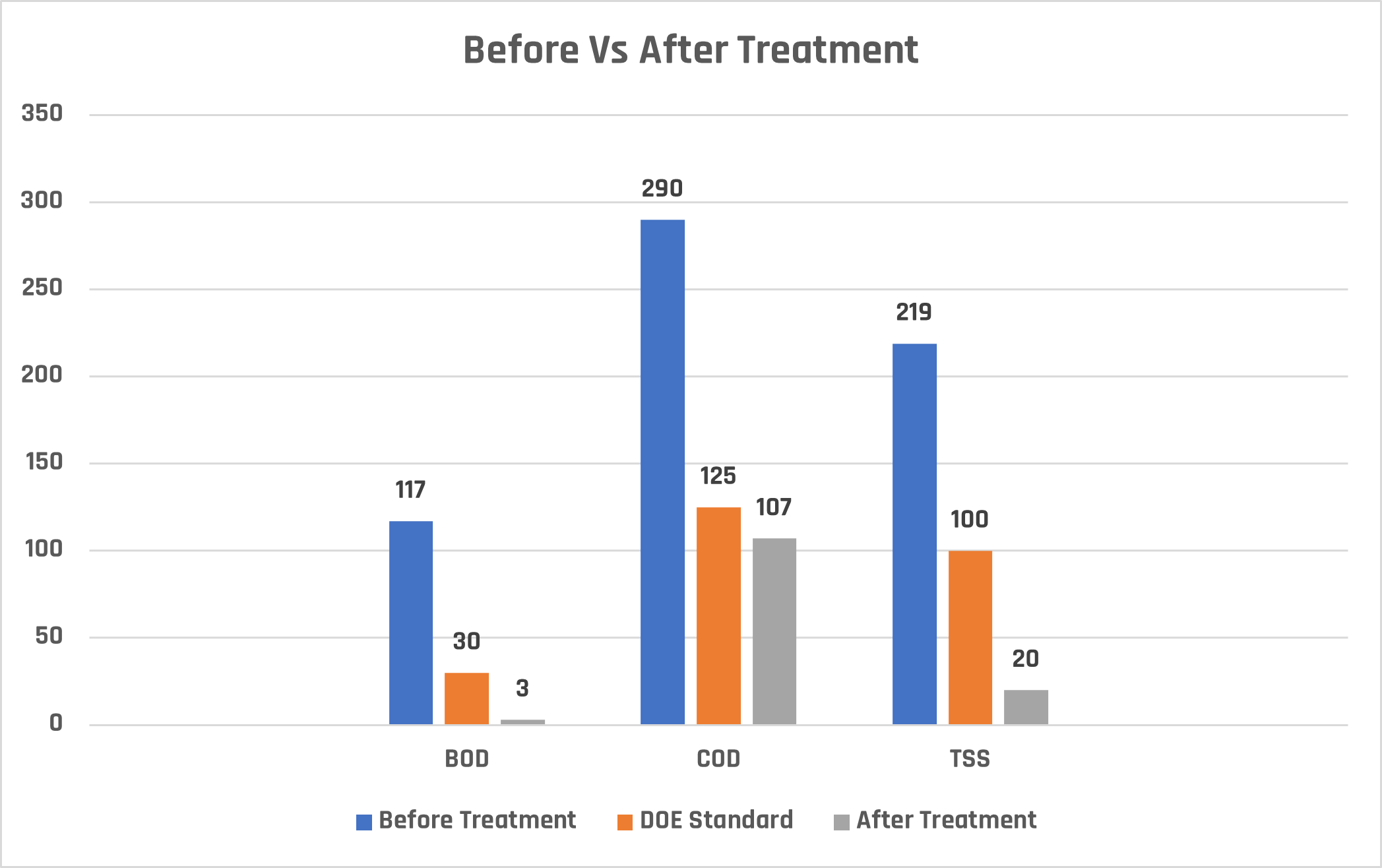

The successful implementation of the MBBR ETP at Ripon Knitwear Ltd has resulted in several significant benefits:

- Reduced environmental impact

- Compliance with DoE & ZDHC regulations

- Sustainable operations

To note, the plant performance was being checked and acknowledged about the performance by renowned 3rd party testing labs such as Hohenstein Bangladesh, ICCDDR’b, etc. The ETP performance and parameters of the outlet were found within the acceptable limit.

Kingsley’s

Achievement

- Achieved remarkably low BOD and COD outflow values, demonstrating the extraordinary efficacy of wastewater treatment.

- The project team accomplished a high degree of cleanliness and disinfection, resulting in no coliform detection.

- Implemented environmentally friendly measures, such as grass turfing over the Effluent Treatment Plant (ETP) module, to improve the project site's aesthetic appeal.

Operating Cost

- The Effluent Treatment Plant (ETP) is very cost-effective. The operating cost is mainly consist of chemical & Electricity cost. The cost of operating our ETP is-

- 16~20 Tk/m3 (0.016~020 Tk/liter)

Conclusion

The Ripon Knitwear Ltd.’s Effluent Treatment Plant is a successful example of using MBBR technology to treat wastewater. Kingsley's competence in design, construction, and commissioning guaranteed that the project was completed on time and successfully. The plant is essential for environmental protection and supporting sustainable practices.

Technology for a

Sustainable Future

Kingsley™ focuses on long term & sustainable future with a reliable technology.

You must be logged in to post a comment.